Water flows steadily through the variable area horizontal pipe, a phenomenon with profound implications in engineering applications. This intricate flow behavior governs the performance of systems ranging from pipelines to aircraft engines, demanding a thorough understanding of its underlying principles.

The governing equations for fluid flow in variable area horizontal pipes, rooted in the conservation of mass, momentum, and energy, provide a framework for analyzing this complex behavior. These equations, however, come with inherent assumptions and limitations, necessitating careful consideration in their application.

Introduction

Fluid flow through variable area horizontal pipes is a fundamental concept in engineering applications. Understanding this concept is essential for designing and optimizing various systems involving fluid transport.

Variable area horizontal pipes are commonly used in industries such as oil and gas transportation, water distribution systems, and chemical processing plants. By understanding the flow characteristics and pressure distribution in these pipes, engineers can optimize system performance, minimize energy losses, and ensure reliable operation.

Governing Equations

The governing equations for fluid flow through variable area horizontal pipes are derived from the principles of conservation of mass, momentum, and energy. These equations are:

- Continuity equation: $\frac\partial \rho\partial t + \nabla \cdot (\rho \mathbfu) = 0$

- Momentum equation: $\rho \frac\partial \mathbfu\partial t + \rho (\mathbfu \cdot \nabla) \mathbfu = -\nabla p + \mu \nabla^2 \mathbfu$

- Energy equation: $\rho c_p \frac\partial T\partial t + \rho c_p (\mathbfu \cdot \nabla) T = k \nabla^2 T + \mu \Phi$

where $\rho$ is the fluid density, $\mathbfu$ is the velocity vector, $p$ is the pressure, $\mu$ is the dynamic viscosity, $c_p$ is the specific heat capacity, $T$ is the temperature, and $\Phi$ is the viscous dissipation function.

These equations are subject to certain assumptions and limitations, such as incompressible flow, steady-state conditions, and negligible gravitational effects.

Flow Characteristics

The flow regime in variable area horizontal pipes can vary depending on the pipe geometry, fluid properties, and flow rate. The main flow regimes are laminar, transitional, and turbulent.

- Laminar flow occurs when the viscous forces dominate the inertial forces, resulting in a smooth and orderly flow pattern.

- Transitional flow occurs when the inertial forces become comparable to the viscous forces, leading to a combination of laminar and turbulent flow characteristics.

- Turbulent flow occurs when the inertial forces dominate the viscous forces, resulting in a chaotic and irregular flow pattern.

The flow regime has a significant impact on pressure drop and energy losses in the pipe.

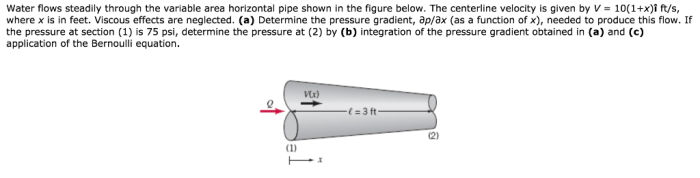

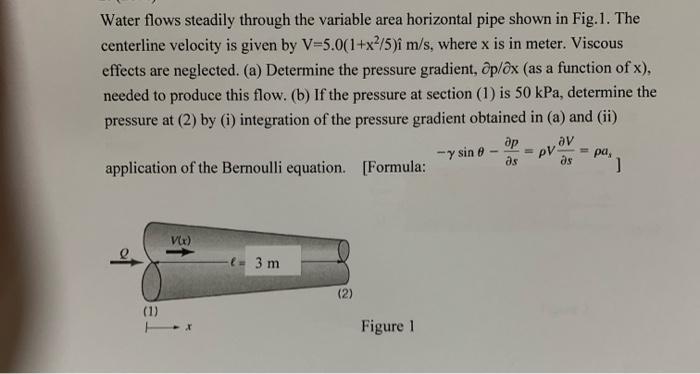

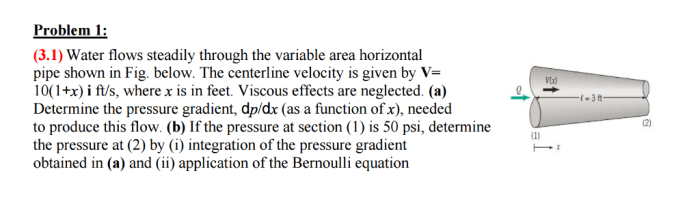

Pressure Distribution, Water flows steadily through the variable area horizontal pipe

The pressure distribution along the length of a variable area horizontal pipe is influenced by the pipe geometry, fluid properties, and flow rate. In general, the pressure decreases in the direction of flow due to friction and energy losses.

The pressure distribution can be represented graphically for different flow regimes. In laminar flow, the pressure drop is parabolic, while in turbulent flow, the pressure drop is more linear.

Energy Losses

Energy losses in variable area horizontal pipes occur due to friction, turbulence, and other factors. The main types of energy losses are:

- Major losses: These losses are due to friction between the fluid and the pipe wall, and they increase with the pipe length and fluid velocity.

- Minor losses: These losses occur at fittings, bends, and other obstructions in the pipe, and they depend on the geometry and flow rate.

Energy losses can be calculated using various methods, such as the Darcy-Weisbach equation or the Moody diagram.

Applications

Understanding fluid flow through variable area horizontal pipes has numerous practical applications in various industries and engineering systems. Some examples include:

- Design of pipelines for oil and gas transportation

- Optimization of water distribution systems

- Analysis of flow in chemical processing plants

- Design of heat exchangers and boilers

- Modeling of fluid flow in biomedical devices

By optimizing flow through variable area horizontal pipes, engineers can improve system efficiency, reduce energy consumption, and ensure reliable operation.

Question & Answer Hub: Water Flows Steadily Through The Variable Area Horizontal Pipe

What are the key factors influencing flow regime in variable area horizontal pipes?

Pipe geometry, fluid properties, and flow rate are the primary factors that determine the flow regime.

How does pressure distribution vary along the length of a variable area horizontal pipe?

Pressure generally decreases along the pipe’s length due to frictional losses and expansion of the flow area.

What are the major types of energy losses in variable area horizontal pipes?

Friction losses, expansion losses, and contraction losses are the main contributors to energy dissipation.